Ura meillä

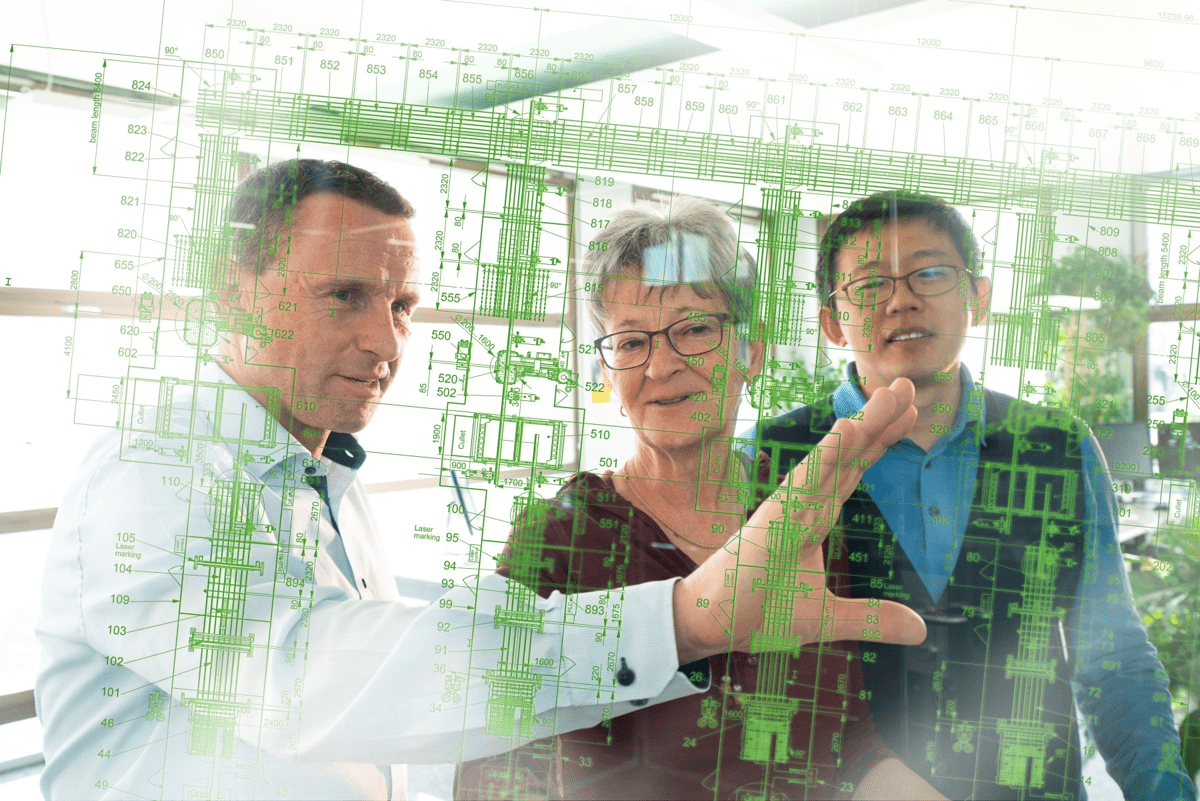

Olemme ylpeinä ja intohimolla luomassa hienointa lasinvalmistusteknologiaa.

Tässä muutamia syitä, miksi työ Glaston voisi sopia sinulle:

-

Kasva kanssamme

Pyrimme jatkuvasti tuomaan uusia teknologiaratkaisuja ja innovaatioita lasinjalostusmarkkinoille. Sinulla on mahdollisuus työskennellä yhdessä alan parhaiden asiantuntijoiden kanssa. Keskitymme korkeaan osaamiseen ja mahdollistamme sinulle innostavan urapolun kehittämisen kanssamme.

-

Seeing it through

on yksi keskeisistä arvoistamme. Se näkyy avoimessa tavassamme tehdä työtä, työtehtäviemme vastuullisuudessa ja asiakaspalvelussamme. Tarjoamme sinulle hyvinvointialoitteita ja varmistamme, että sinulla on kaikki, mitä tarvitset työssäsi etenemiseen.

-

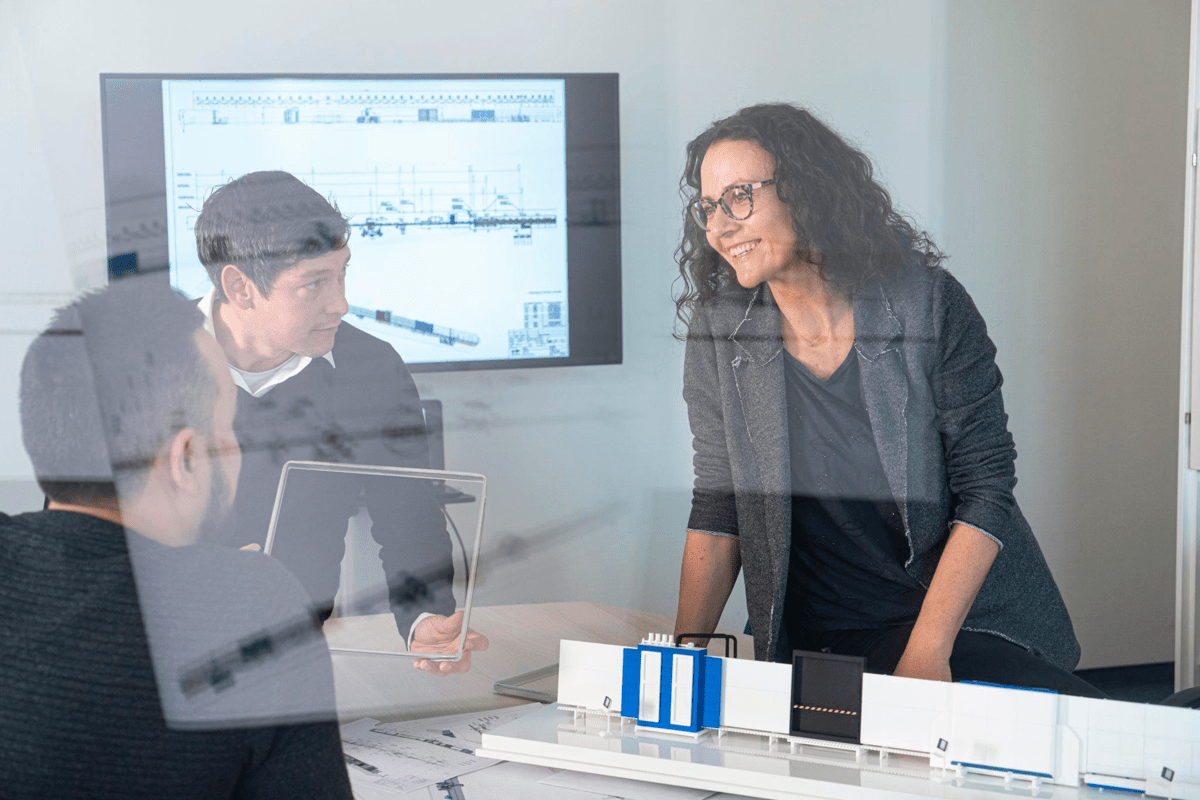

Paras asiakaskokemus

Meille parhaan mahdollisen asiakaskokemuksen luominen on työmme ydin. Olemme ylpeitä voidessamme auttaa lasinjalostajia saavuttamaan tavoitteensa tukemalla heitä nykyaikaisimmalla teknologialla.

Avoimet paikat

-

Sales Support Trainee, Tampere Finland

Tampere, Finland · Hybridi

-

Ausbildung Fachlagerist (m/w/d)

Apprenticeship · Neuhausen (Enzkreis), Germany

-

Elektriker (m/w/d) Schaltschrankbau

Neuhausen (Enzkreis), Germany

-

Leiter Qualitätssicherung (m/w/d)

Neuhausen (Enzkreis), Germany

-

Facharbeiter Zerspanung (m/w/d)

Valmistus · Neuhausen (Enzkreis), Germany

Henkilöstöetujamme...

-

Hybridityö ja joustavat työajat

-

Työterveyden lisäksi kattava terveysvakuutus

-

Jokaisella mahdollisuus mielenhuoltoon

-

TBC-verkostossa 100 tilaisuutta vuodessa kehittyä

-

Tukea harrastuksiin - ja unelmiesi pyörä työsuhde-etuna

-

Sairaan lapsen hoitopalvelu

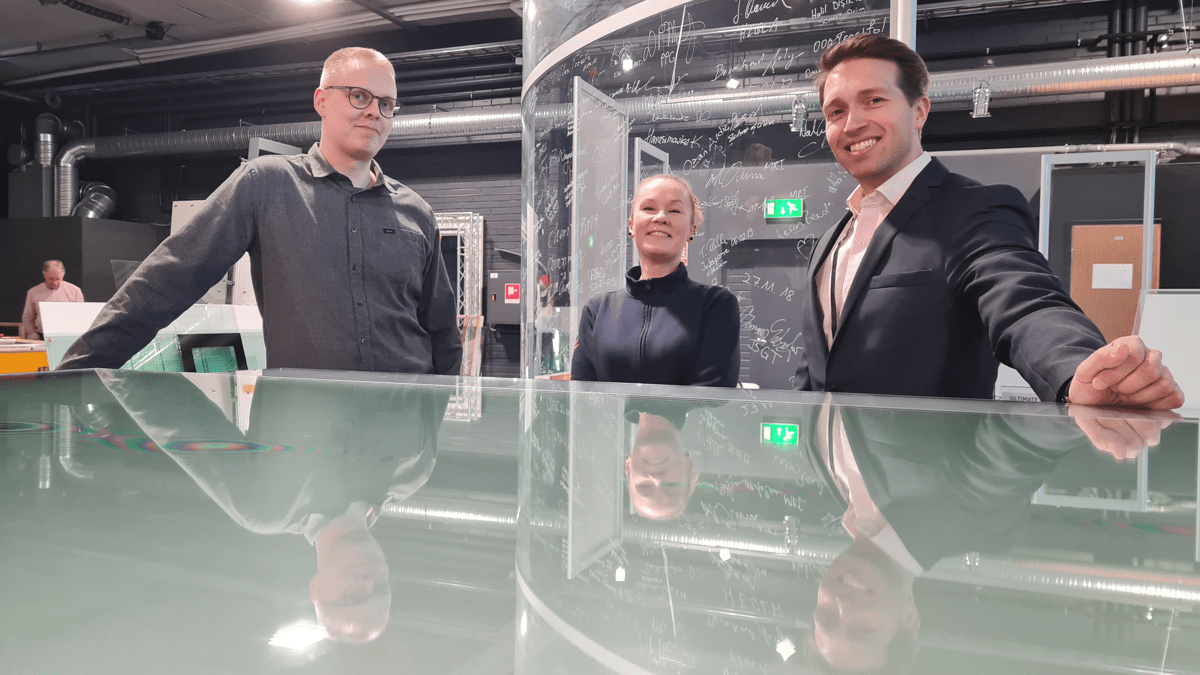

Meet our people

-

Anna Holmqvist

"I highly appreciate the deep personal contact between our people and customers. Getting a follow-up order from an old customer and engaging in another mutual project always gives me extremely good vibes."

- Anna, Director, Project Management, Glaston Heat Treatment Technologies

-

Hamed Tabatabaei

"By traveling for work to various cities, countries and continents, I have also had the pleasure to learn more about different cultures and people along the way. And this is something I find to be priceless."

- Hamed, Senior Technical Support Engineer

-

Melisa Tulppo

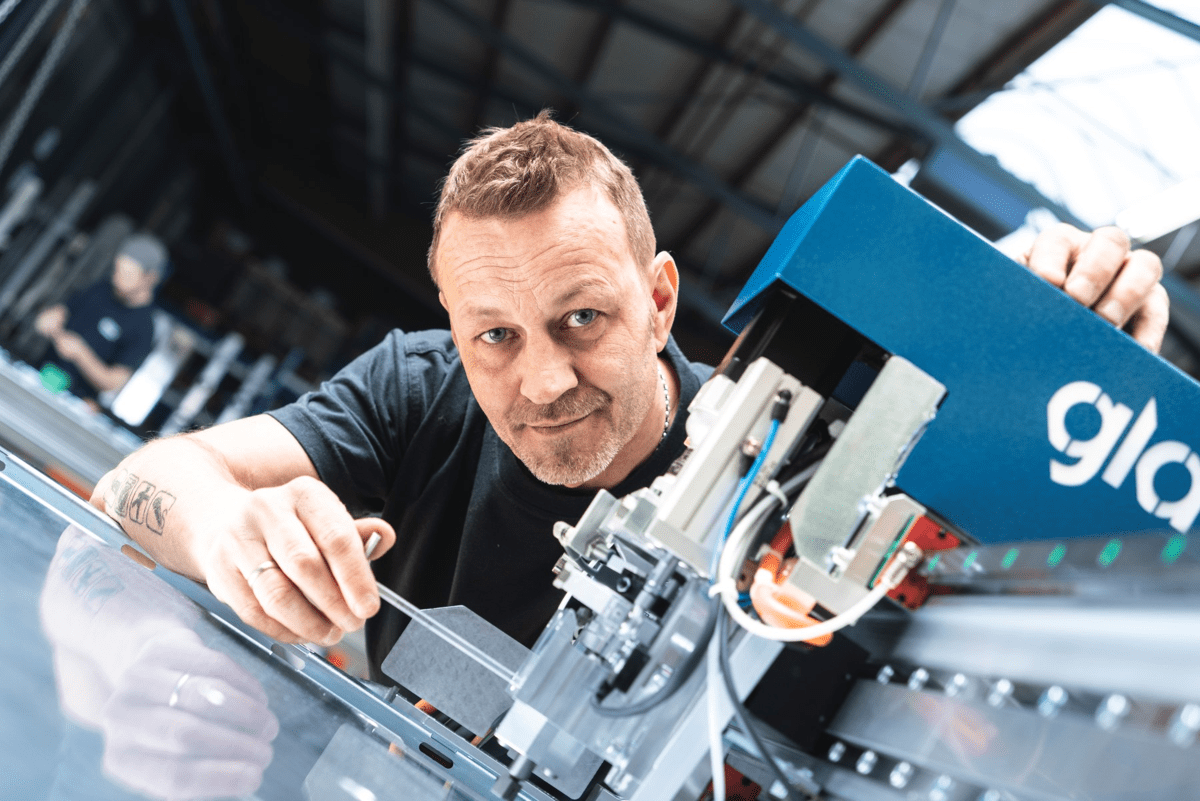

"The best thing about my job is that I get to work with my hands at my own pace. Special equipment, which our customers have ordered, also adds diversity to my job. I can truly say that my work is so varied and diverse, it never gets boring."

- Melisa Tulppo, Assembly worker

-

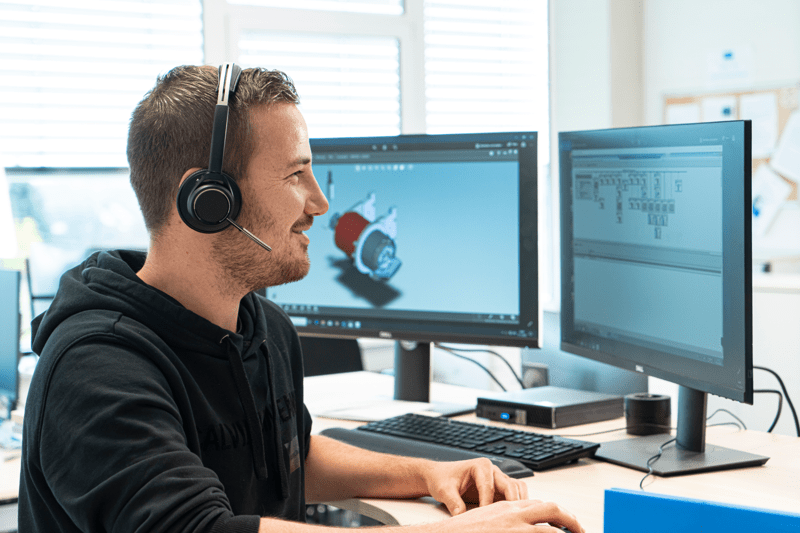

Philipp Pfeffinger

"Many of my colleagues have been with the company for years. We know each other well and appreciate each other. The company thrives from the knowledge and experience of its employees."

-Philipp, Sales Engineer

-

Vesna Pavlovic

"This has been, and still is, an adventurous journey and consistent learning curve that has helped me develop my leadership and management skills in the more than 10 years I have been with the company."

-Vesna, Area Sales Manager in EMEA

-

Kaijun Xin

"I appreciate the fact that Glaston supports job change, professional growth and expertise development for those who want it. This really helps maintain a high level of employee motivation and commitment."

- Kaijun, Product Manager

Glaston yrityksenä

Olemme johtava lasinjalostusteknologian ja -palveluiden tarjoaja, joka vastaa maailmanlaajuisesti lasinjalostustarpeisiin arkkitehtuuri-, ajoneuvo-, aurinkoenergia- ja näyttöteollisuudessa.

Työskenteletkö jo yrityksessä Glaston?

Osallistu rekrytointiin, löydä seuraava kollegasi.